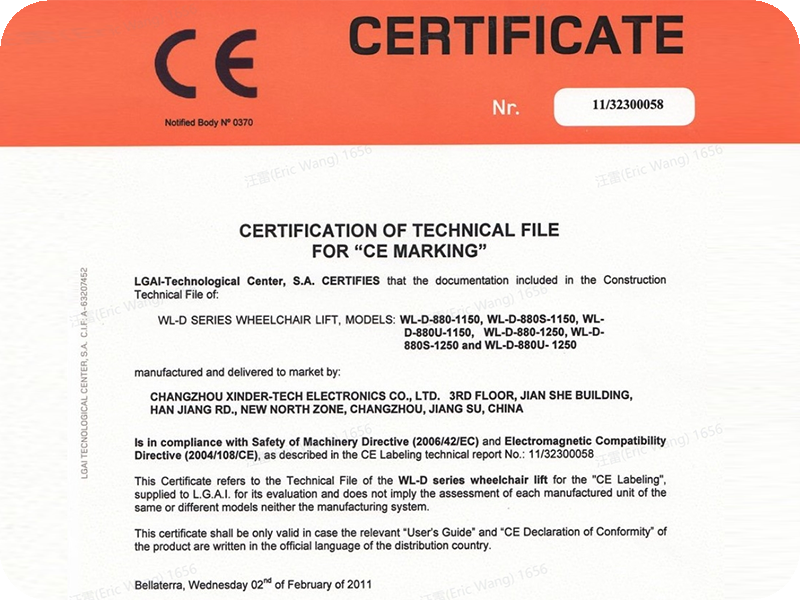

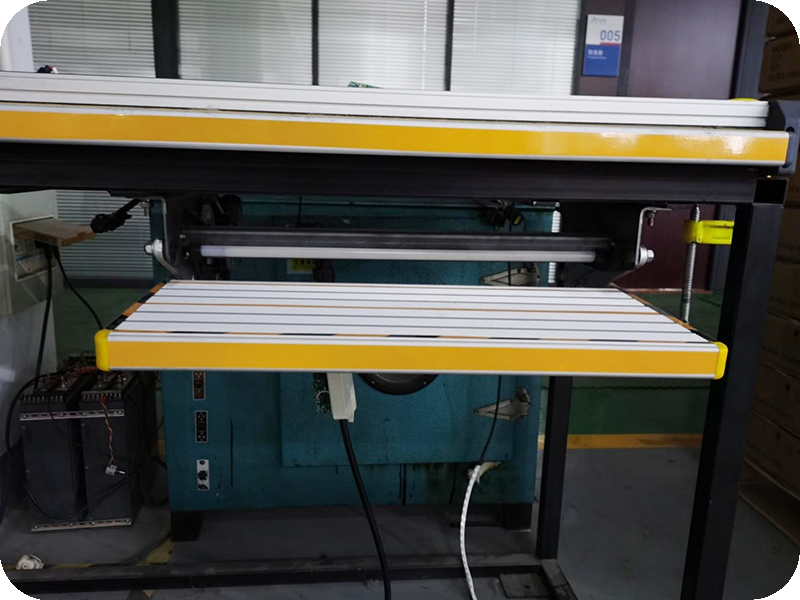

Safety is the first criterion! Xinder-Tech has always prioritized product safety for barrier-free travel. Over the years, we have insisted on conducting various stringent tests on our products without sparing any costly investment. In our safety labs around the world, our products have undergone 100+ tests, including crash tests, durability tests, high and low temperature tests, etc., which are more stringent than the national standards. It is with the persistent pursuit of safety that Xinder-tech has achieved great results in product safety. Products such as Swivel seats not only meet Xinder's corporate standards, national standards, and European Union export standards, but also meet the more stringent standards of the OEMs, and are far superior to similar competing products on the market.

This is not only the test of product safety performance, but also the respect for life and commitment to safety. As the leader of domestic vehicle accessibility equipment, Xinder-tech has proved with its own practical actions that safety is not a slogan, but a real guarantee. We believe that only by truly emphasizing product safety can we win the trust and reputation of our customers!